Technical Brief-Decorative Trivalent Chromium Plating

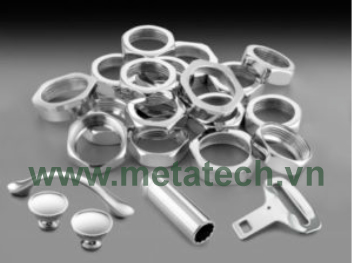

This article covers recent regulations and performance requirements that have made making the switch from decorative hexavalent chromium plating to trivalent chromium plating a necessity. Additional information will also be provided on the operating parameters of trivalent chromium plating processes as well as some troubleshooting and electrolyte composition.

History: In 1939 the U.S. Bureau of Mines began research and developed a electrowinning process in the 1940s. Union Carbide also began research on trivalent chromium at this time. Together they broke down many obstacles in the art of trivalent chromium plating. Albright Wilson further developed the process, their big contributions were additives to prevent the formation of hexavalent chromium and a method to precipitate metallic impurities. The Albright Wilson chemistry was a mixed sulfate/chloride electrolyte. There were also other developments that were sulfate only electrolytes.

Performance: In 1975 ASTM conducted tests showing that trivalent chromium plated deposits performed as well or better than hexavalent chromium in outdoor exposure tests. Just recently USCAR performed outdoor exposure tests and confirmed that trivalent chromium performs as well or better than conventional hexavalent chromium in outdoor exposure testing.

Furthermore, chloride or mixed sulfate/chloride processes outperformed sulfate chemistries in calcium chloride (highly corrosive) environments.

Performance History: Trivalent chromium has been used in exterior applications for many years, with the trucking industry having specified trivalent chrome for the past 30 years. The sulfate/chloride process has shown indefinite electrolyte life, process stability, ease of use, and excellent exterior corrosion performance. The field performances of trivalent chromium confirm test results performed by ASTM. The recent testing by USCAR has also confirmed these results. The advantages of improved covering power and uniform thickness have eliminated the need for use of auxiliary anodes for plating difficult geometries.

Regulations: Regulation changes within the European Union have further accelerated the switch to trivalent chromium plating. With hexavalent chromium plating set to be eliminated in the European Union by 2021, many manufacturers; especially global manufacturers, have already specified or are in the process of specifying trivalent chromium on their blueprints to meet the new regulations. OSHA and the EPA continue to adopt legislation that further justifies switching from hexavalent to trivalent chromium plating.

Recent Innovations: The technology has continually improved with trivalent chromium as well as the level of experience with the operation of the process. New installations using trivalent chromium have less rejects and easier control than hexavalent chromium. Combine this with the waste treatment advantages and it is a clear choice for the future.

Typical Operating Parameters for Sulfate/Chloride Electrolytes

Agitation: Mild agitation is necessary to replenish the cathode film and maintain temperature uniformity. In general, lower agitation can increase coverage but it can reduce the plating rate.

pH: pH of the solution affects both the plating speed and the low current density coverage. Generally Lower pH produces higher plating speeds but at the expense of low current density coverage. Higher pH will result in slower plating speeds, but will improve the low current density coverage. The pH is typically maintained between 2.5 and 3.5 for most electrolytes.

Temperature: The temperature is usually maintained between 80 - 100˚F. Higher temperatures will increase the plating rate but at the expense of reduced coverage. Lower temperatures tend to improve the deposit color.

Cathode Current Density: In general, the cathode current density should be as low as possible to produce satisfactory work. This will in turn reduce any requirement for cooling and rectifier capacity as well as decrease the consumption of additives.

Increasing current density may not result in improving deposit thickness because cathode efficiency decreases with increasing current density. Although this will result in the production of good deposit distribution (throwing power), thickness will be a factor of time rather than current density. Typically, chromium will be deposited at a rate of approximately 4-5 millionths of an inch per minute (0.10 - 0.125 microns/minute) regardless of the cathode current density. The typical cathode current density range is 8.1 ASD and up.

Anode Current Density: Special graphite anodes are typically used and the anode current density is usually maintained below 5 ASD. The graphite anodes last indefinitely under proper production conditions.

Typical Solution Composition for Sulfate/Chloride Electrolytes

Make-Up Salts: These salts are usually provided to supply the chromium salts, conductivity salts, and other specialty compounds for a new bath make-up. These materials are usually added in amounts specified by the manufacturer. Typical make-up quantity is normally 400 g/L. This concentration is easily maintained by specific gravity or chemical analysis.

Complexing Agent: This component is necessary to complex the chromium. Trivalent chromium must be plated from a complex. This component is maintained on an ampere-hour basis and verified through chemical analysis.

Mist Suppressants: Mist suppressants are usually added to minimize misting. Deposit uniformity is sometimes improved in addition to some metallic impurity tolerance in certain instances.

Operational Advantages for Sulfate/Chloride Electrolytes

The operational advantages of trivalent chromium are clear. The cathode efficiency of the trivalent chromium decreases as the current density increases this in turn makes it nearly impossible to produce burnt deposits. This allows the use of higher current densities and better covering power when compared to hexavalent chromium deposits.

SERVICE:

METATECH consults on the design of the plating process, synchronously provides Cr3+ plating additives, special graphite electrodes, filter resins and all additives for a plating line.

Contact:

METATECH MATERIAL TECHNOLOGY JOINT STOCK COMPANY

Hanoi office address: S02 - D'Eldorado Building 1, 659A Lac Long Quan, Xuan La Ward, Tay Ho District, Hanoi City

HCM office address: 86/59 Pho Quang, Ward 2, Tan Binh District, Ho Chi Minh City.

Website: https://metatech.vn

Fanpage: https://www.facebook.com/metatechvietnam

Hotline in Hanoi area: 0988.956.546 or 0989.491.366

Hotline in HCM area: 0963.867.366 or 0969.678.756